Air chillers are a type of HVAC equipment that are used to cool the air in buildings and industrial facilities. They work by removing heat from the air and transferring it to a fluid, such as water or refrigerant. They offer several advantages such as precise temperature control, improved air quality, lower cost of operation and maintenance, and energy efficiency. However, they also have some limitations such as higher initial cost and maintenance, and the need for a larger space.

Air Chiller

-

An air chiller is a type of HVAC (heating, ventilation, and air conditioning) equipment that is used to cool the air in a building or industrial facility. Air chillers work by removing heat from the air and transferring it to a fluid, such as water or refrigerant. This cooled fluid is then used to cool the air in the building through the use of air handling units or other types of cooling equipment.

One of the major benefits of using an air chiller is its ability to provide precise temperature control. Many air chillers are equipped with sophisticated controls that allow users to set and maintain specific temperature levels throughout a building or facility. This can be particularly useful in industrial settings where precise temperature control is critical to the production process.Another benefit of air chillers is their ability to improve air quality. Many air chillers are equipped with air filtration systems that remove contaminants, such as dust and allergens, from the air. This can help to improve the overall air quality in a building or facility and can be particularly beneficial for people with allergies or respiratory problems.

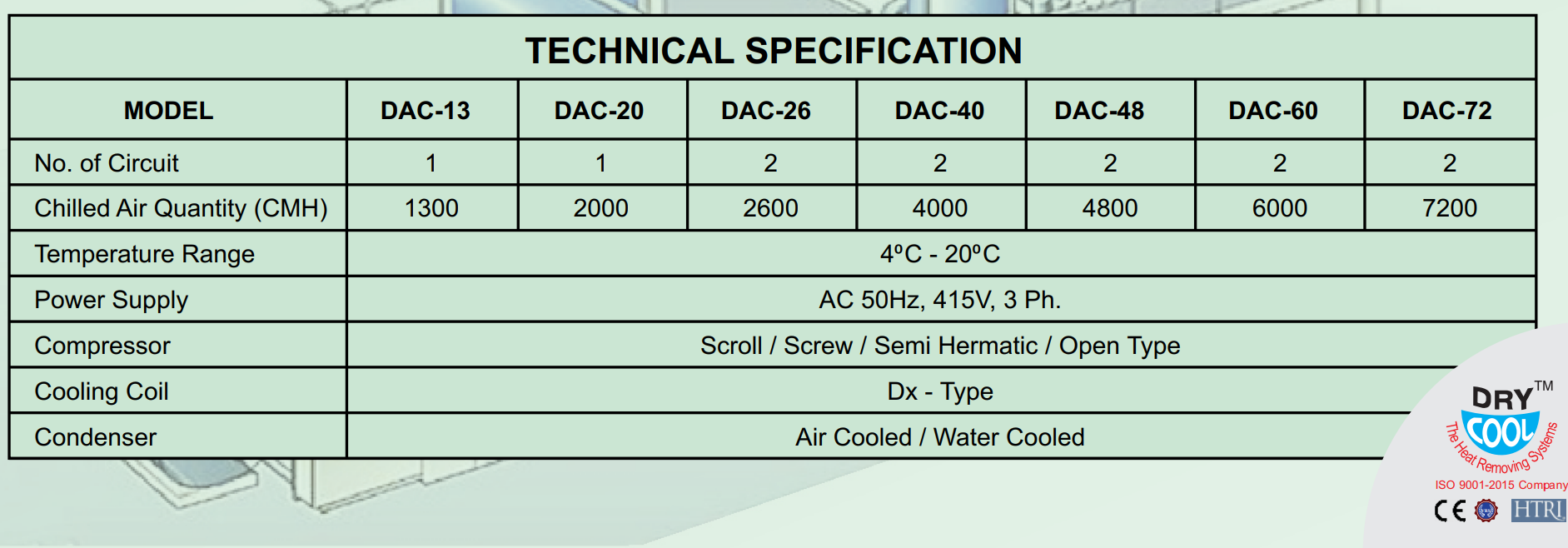

DRYCOOL DAC Series Chillers come with cooling capacity from 9 TR to 30 TR with an operating temperature of 5° C to 20°C in ambient air temperatures of up to 40°C. The Air Chiller works by soaking warm temperatures from treated liquid. This sort of equipment uses air to chill the coolant and delivers air to the heat exchanger.

There are several different types of air chillers available on the market, each with their own unique characteristics and advantages. Some of the most common types of air chillers include:

Water-cooled air chillers: These types of air chillers use water as the fluid to transfer heat away from the air. They are often used in large industrial facilities, such as power plants and factories, where large amounts of heat need to be removed from the air.

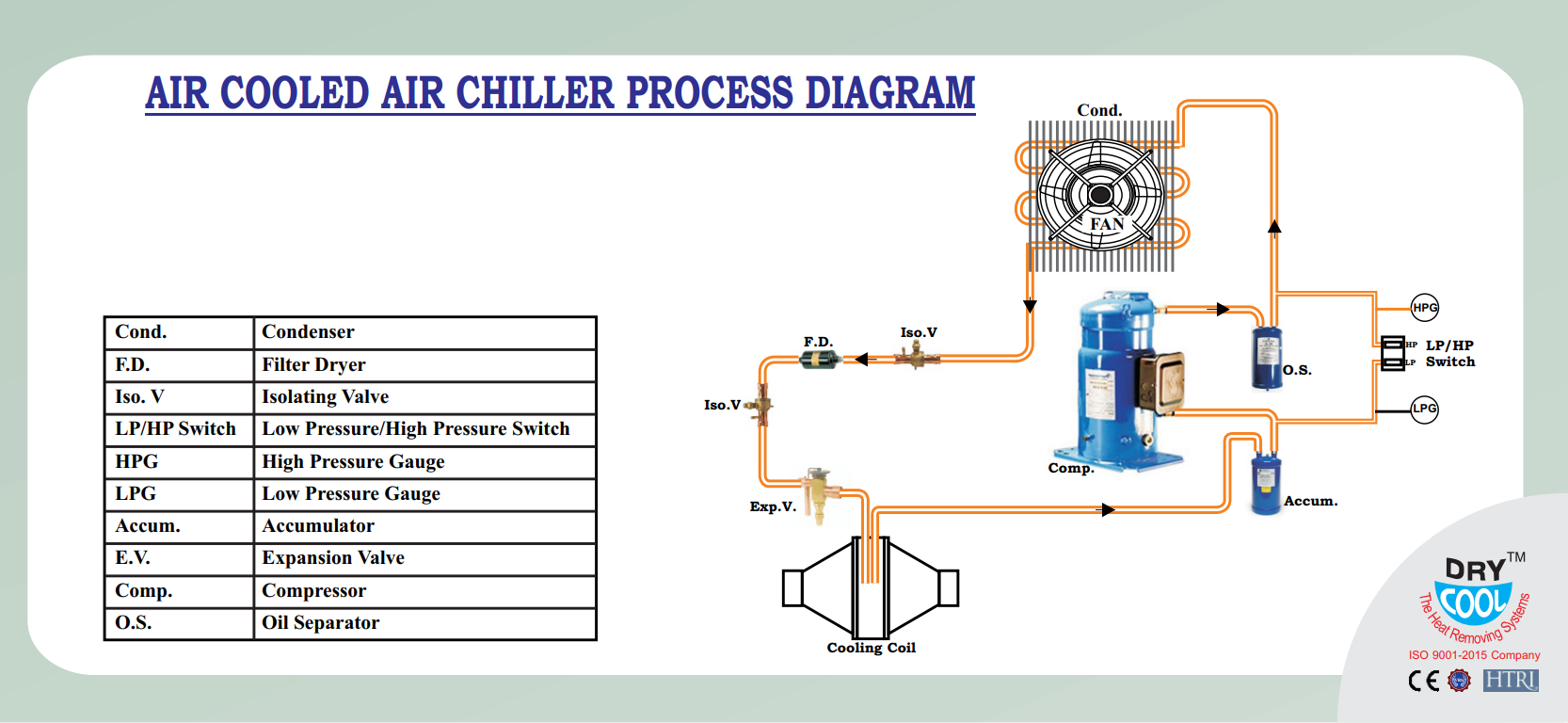

Air-cooled air chillers: As the name suggests, these types of air chillers use air as the fluid to transfer heat away from the air. They are often used in smaller buildings or facilities where the amount of heat to be removed is not as large.

Screw compressor air chillers: These types of air chillers use a screw compressor to compress the refrigerant and transfer heat away from the air. They are often used in large industrial facilities and are known for their high efficiency and reliable performance.

Scroll compressor air chillers: These types of air chillers use a scroll compressor to compress the refrigerant and transfer heat away from the air. They are often used in smaller buildings and facilities and are known for their low noise levels and high efficiency.

Air chillers also have a lower cost of operation and maintenance than other types of HVAC equipment. Because they use a fluid, such as water or refrigerant, to transfer heat away from the air, they do not require the same level of maintenance as other types of equipment, such as boilers or electric heaters. In terms of energy efficiency, air chillers use less energy than traditional cooling methods, such as window air conditioners and portable air conditioners. They also have a longer lifespan and are more durable, which means less need for replacement and repair.

However, air chillers also have some limitations. They are typically more expensive to purchase and install than other types of HVAC equipment, and they can be more complex to operate and maintain. Additionally, they can be quite large and may take up a significant amount of space, which can be a problem in smaller buildings or facilities.

UNIQUE FEATURES

• Energy efficient and reliable scroll compressor with hermetically sealed suction gas cooled motor.

• Each model is equipped with PLC based control platform. Control features include 2 line 16 character LCD display, onboard fault indication with audio alarm.

• Accurate temperature control with the help of modulating hot gas bypass valve.

• Intelligent program to save energy for dual compressor chiller circuit specifically for part load application.

• Display of set value and actual value on screen.

• Display of return air temperature on screen.

• Scroll and function buttons allow you to navigate the chiller’s control platform.

• Neatly organized internal component layout.

• Proven component suppliers i.e. Copeland, Danfoss, Siemens, Emerson, IFM have been chosen for ultimate reliability and availability.

• All chillers are factory tested under load prior to shipment.

• Finned and Tube Evaporator – high surface area due to internally grooved copper tube, generously sized for industrial environment and tested to 300 PSIG with lower pressure drop.

• RTD temperature sensors yield higher precision and repeatability than thermocouples.

• Three phase monitor protects against unit damage due to phase reversal or loss of phase.