Drycool Systems is the most preferred manufacturer to procure Industrial Water Chillers and Cooling Towers in Indonesia. We have built our reputation as a highly trustworthy manufacturer of these industrial chillers. We focus on innovation and technology to constantly improve our products with the changing market trends.

Industrial chillers in Indonesia

-

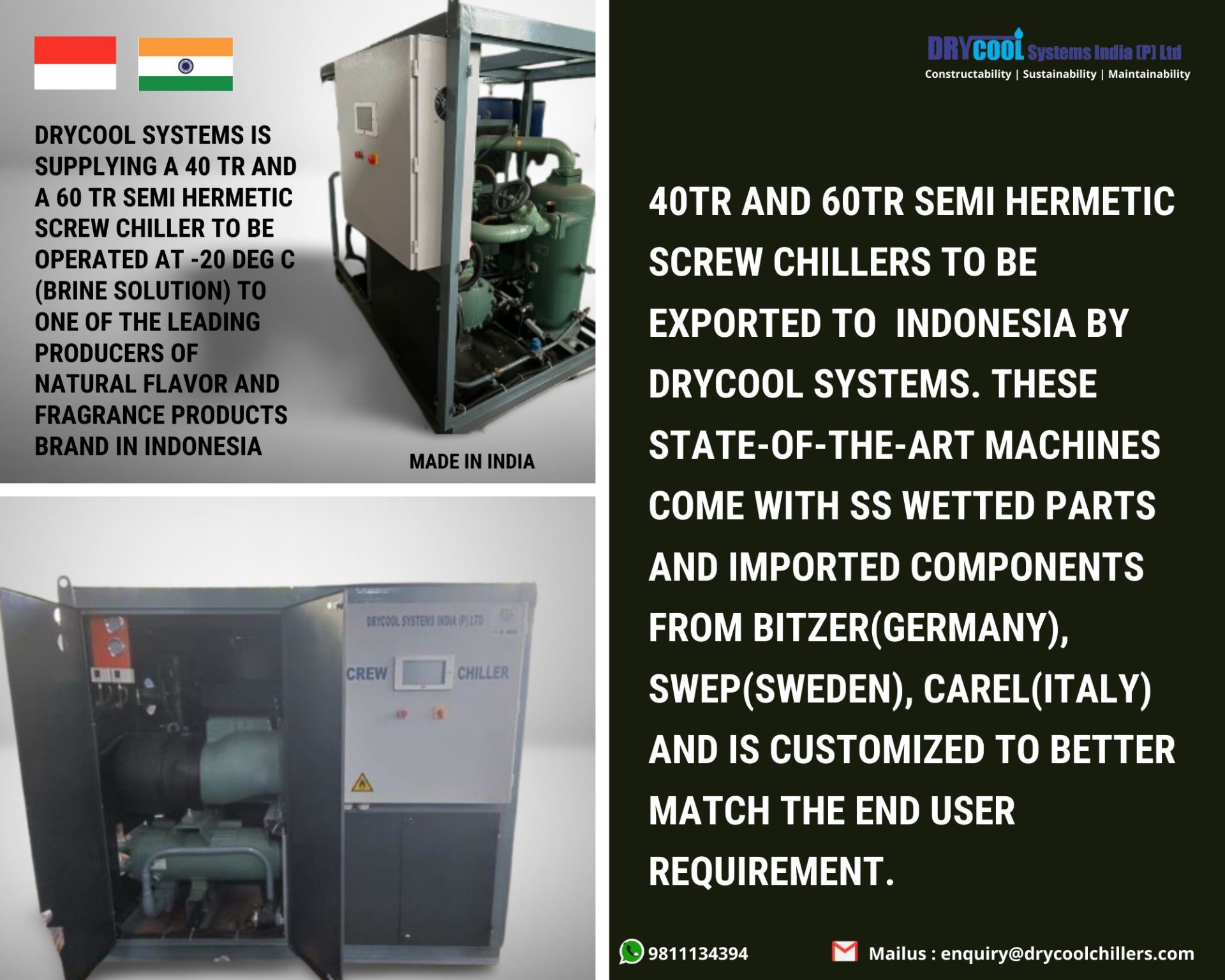

We have a state-of-the-art manufacturing facility in India to manufacture customized chillers and cater to the demands of our OEMs (plastics, concrete, RO water, brewery, and fermentation, chemical and pharmaceutical, hydrogen refuelling, medical devices, anodizing, food, refrigeration, HVAC and marine applications) in Indonesia. Our team comprises of qualified welders, Skilled fitters and diligent workers put hours into every single unit to ensure a quality product.

Tested in accordance with the latest international standards and in different challenging conditions, these units promise unmatched performance for years after the purchase. This has made us one of the highly appreciated Industrial Water Chillers Manufacturers in Indonesia.

Our company has emerged as one of the most illustrious Low-Temperature Industrial Water Chillers Exporters and Suppliers in Indonesia. The industrial chillers provided by Drycool are energy efficient and provide a high coefficient of performance. We are already supplying these units to many firmly established organizations in Indonesia.

Special features of Drycool’s Robust and Energy Efficient Water Chiller for Indonesia

• Chillers are designed to attain brine, glycol and methanol temperatures upto -50 deg C and can work on condensing temperatures as high as 57 deg C

• Energy efficient reciprocating compressors from Denmark (Danfoss), Germany (Bitzer), and Italy (Dorin) with piston and cylinders for compression of refrigerant and ease of maintenance

• Customization to add flame proof motors (Bharat Bijlee/ Crompton/ ABB/ Siemens) on open drive reciprocating compressors as per requirement.

• Eco friendly freon gas R-134a / R-407C/ R-404a

• Customization to use Ammonia (NH3) as a refrigerant

• Electronic expansion valve for minimum superheat, energy efficiency and precise temperature control

• Multiple circuits including brine or water pumps and stainless-steel storage tanks on skid

• Wheels provided on the skid for extra ruggedness for mobile operation

• Low Fins per inch count and high condensing surface area with blue coated fins for easy maintenance

• Shell and tube type evaporators with high-flow design, ready to handle fluid debris and suspended particles. Customization to use SS 316 shell and SS316 tubes is also available.

• Weatherproof design with IP55 / IP65 level protection

• Customization to add Siemens/Allen Bradley/Schneider’s automatic PLC, HMI, Industrial PC and Scada units with remote operation and data logging facilities

• Customization to use ATEX/PESO certified instrumentation and ATEX certified compressors

• Third Party ATEX Chiller Certification can be provided

• Automatic stepped capacity control from 25%-50%-75%-100%, or stepless capacity control, from 25% to 100%.