Refrigerated Air Dryers

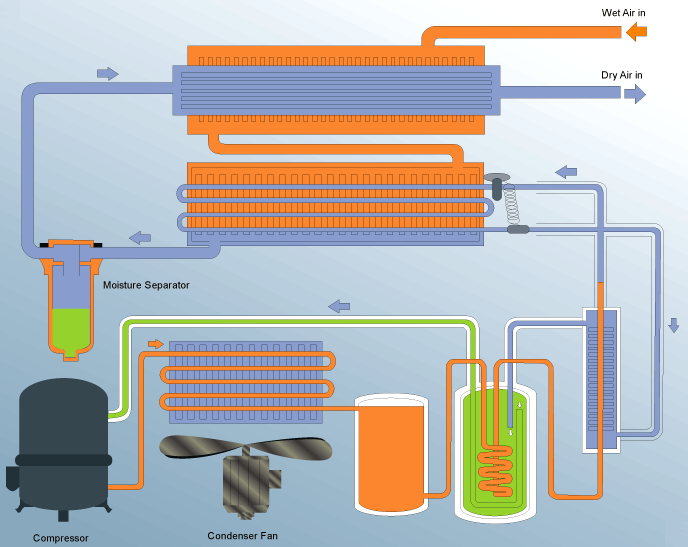

Compressed air with saturated water vapor enters the dryer’s pre-cooling device, in which, the entered hot air is cooled down by the outgoing cold air partly, thus reducing the load on the system (this process is pre-cooling). Pre-cooled air enters the evaporator. Here, heat released by the air is absorbed by media and the air reaches the pre-set temperature (2 ~ 4℃). After being cooled, the water vapor in the air condenses into droplets and is separated from the air by steam separator and then flows out of the dryer through automatic drainer. Leaving the separator, cold air enters into the pre-cooling device’s shell side for heat exchange with hot air in the inlet and leaves the dryer after being heated to a temperature about 10 ℃ lower than that of the inlet air. This reheating prevents the second moisture condensation in the outside exit air pipeline and downstream pipeline, increases the energy of the air and improves the effectiveness. In addition, after passing through the dryer, solid dust of over 3μ in the compressed air is all filtered, and the air source quality reaches the clean and dry requirements.

-

MODEL CAPACITY

CMHAPPROX

DIMENSION

L x B x H(mm)AIR

CONNECTIONMOTOR

H.P.DR-1 7 700 x 500 x 500 1/2” BSP 1/6 DR-2 43 700 x 500 x 500 1/2” BSP 1/3 DR-5 86 900 x 600 x 800 3/4” BSP 5/8 DR-7 129 900 x 600 x 800 3/4” BSP 1/5 DR-10 171 900 x 600 x 1000 1” BSP 1 DR-15 257 1000 x 600 x 1000 3/2” BSP 1.5 DR-20 342 1200 x 700 x 1000 2” BSP 2 DR-25 428 1300 x 800 x 1200 2” BSP 3 DR-30 415 1300 x 800 x 1300 2” BSP 3 DR-40 685 1400 x 800 x 1400 2.5” BSP 5 DR-50 857 1500 x 1000 x 1500 3” BSP 5 DR-65 1114 1500 x 1200 x 1500 3” BSP 7.5 DR-75 1285 1500 x 1300 x 1500 3” BSP 7.5 DR-85 1457 1700 x 1300 x 1600 4” BSP 7.5 DR-100 1714 1800 x 1400 x 1800 4” BSP 10 DR-120 2057 1800 x 1500 x 1800 4” BSP 10 DR-150 2571 1900 x 1600 x 2000 4” BSP 15 DR-180 3085 1900 x 1600 x 2000 6” BSP 15 DR-200 3485 2100 x 1800 x 2000 6” BSP 20 DR-250 4285 2200 x 1900 x 2000 8” BSP 25 DR-300 5142 2400 x 2000 x 2000 8” BSP 30 -

- Economical in power consumption in comparison with other type of dryers for equivalent dew point.

- Innovative Heat Exchanger ensure max. Heat transfer & low pressure drop.

- In built safety devices for compressor, condenser etc.

- Consistent Dew point over wide range of flows.

- Simple design, easy access to all parts requiring almost no maintenance.

- Modular skid mounted unit in robust industrial cabinet is prewired and piped. Inbuilt air, electrical & drain connection. The dryer is ready to start saving your money.

- High quality product due to stage wise inspection & testing before dispatch.