CALL: +91-9811134394

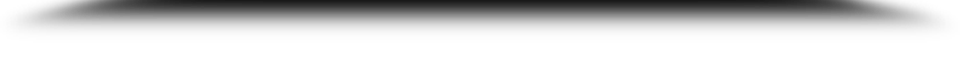

Water Cooled Screw Chiller

Drycool System’s water cooled screw chiller is specially designed to work even in extreme tropical weather conditions. They will still maintain high energy efficiency in any weather condition. We will offer the best possible equipment being the best chiller supplier in India. Our choice of equipment and the design is completely based on offering high-quality standards. We follow the international standard of manufacturing and testing for offering the best quality of equipment.

Buy water cooled screw chiller in a very reasonable price with better quality. All the installed screw chiller are completely operation friendly which will be backed up by the skilled and experienced engineering team. Drycool Systems is the best chiller manufacturers in India who will offer high-quality tenders in fabricating the best manufacturing unit with the option of CFC-free refrigerants. The refrigerants which are used in water-cooled screw chiller are R407C & R134A. It is made out of a stainless-steel chilled water expansion tank along with a process pump to offer the best chilling condition.

Our precision range of Water Cooled Screw Chiller with Multiple Compressors is of world class quality and is fabricated in our state-of-the-art manufacturing unit having an option of using CFC free refrigerants r-407c & r-134a complete with in-built process pump and stainless steel chilled water expansion tank.

screw chillers are rated for an ambient of up to (+) 50°c and cooling tower water temperature up to (+) 37°c at the inlet of the condenser. Our range is manufactured using reputed screw compressors from bitzer (Germany) and frascold (Italy). Fully microprocessor based, these chillers are suitable for process cooling applications from (+) 20°c upto (-) 40°c. We offer these multiple screw compressors in one machine but having separate and individual refrigeration circuits.

The pillars are having the ability to maintain the range of (+) 50⁰C and for the cooling tower water temperature, it can be ranging around (+) 37⁰C. The temperature is consistently maintained at the inlet of the condenser which is the favorable equipment in the product. Every water-cooled screw chiller is integrated with a screw compressor coming from Frascold in Italy and Bitzer in Germany. They are completely microprocessor-based and it is much more suitable while processing cooling applications ranging from (+) 20⁰C up to (-) 40⁰C.

In our screw chiller we are having different water-cooled screw compresses installed in a single machine that is completely separate from the refrigeration circuits. This will give the advantage of maintenance with no downtime. The machine can be properly maintained and updated without any halting of the production in the industries. Drycool Systems is a renowned chiller manufacturer in India along with remarkable market growth in the industry.

We are offering various functionalities with water-cooled screw chillers which include easy operation, less maintenance, and hassle-free service life. Screw chillers are mostly used for cooling water in various industries including food processing, chemicals, etc.

Prominent Features of Drycool System’s Water Cooled Screw Chillers:

- It is completely energy-efficient.

- Get operation-friendly refrigerants R134A.

- The product is completely environmentally friendly.

- Get the latest reliable and efficient version of the screw compressor from Europe.

- Part load and full load energy efficiency using multiple and single refrigeration circuits.

- Evaporator and DX are completely factory-made and tested. They are made by maintaining the high International standard of manufacturing.

- Get precise temperature control along with increased efficiency through electronic expansion valves.

- Amazing is having a fully automatic PLC unit which is useful for data logging facilities and remote operation.

- Get the complete excess capacity control with 25% to 100% adaptive varying process load.

- It is having high following factors with extra tube thickness, increase condensing area, and high floor design. It will offer high operational reliability, high energy efficiency along easy maintenance.

- It is also having TC motor winding protection.

- Built-in oil separator.

- Discharge temperature controller along with protection.

- Completely efficient and reliable with low noise levels.

- It is tested according to the European standards and ARI.

- 5 to 6 patented profile design.

- Get extreme oil level switch with proper differential pressure switch.

- Excellent performance along with smooth operation.

- Eco-friendly and robust construction.

- Get quick chilling functionality.

- User-friendly design.

- High quality with long working life.

- Low maintenance cost.

Advantages of Drycool System’s Water Cooled Screw Chiller:

- Water-cooled chillers are having capabilities for handling large cooling loads as the equipment will be using the water evaporation technique to dissipate heat. This technique is fully energy-intensive compared to blowing air around hot surfaces. The blowing air technique is used by Air Cooled Screw Chiller which is completely different from Water Cooled Screw Chiller. Water is having more heat capacity compared to air and it can easily remove heat compared to air.

- Water Cooled Screw Chiller is having capabilities of handling large loads according to the floor space by comparison to Air Cooled Screw Chillers.

- All the Water Cooled Screw Chiller are having a simple design and do not need a second set of pumps for the condenser.

- Every Water Cooled Screw will last longer as they are generally placed inside the building and its deterioration rate is much slower compared to Air Cooled Screw Chiller.

The various operating voltages of these chillers are:

- 380 / 400 volt ac / 50 hz.

- 460 volt ac / 50 hz.

- 380 volt ac / 60 hz.

- 460 volt ac / 60 hz.

-

Model Capacity (TR) QTY. Flow Rate (CMH) DCM-W-60 60 TR 2 36.0 DCM-W-80 80 TR 2 48.0 DCM-W-100 100 TR 2 60.0 DCM-W-115 115 TR 2 69.0 DCM-W-150 150 TR 2 90.0 DCM-W-175 175 TR 2 105.0 DCM-W-250 250 TR 2 150.0 DCM-W-300 300 TR 2 180.0 DCM-W-350 350 TR 2 210.0 -

- TC motor winding protection.

- Oil level switch and oil differential pressure switch.

- Latest 5 to 6 patented profile design.

- Highly reliable, efficient and low noise levels.

- Built – in oil separator.

- Discharge temperature protection with its controller.

- Tested in accordance with ARI / European standards.